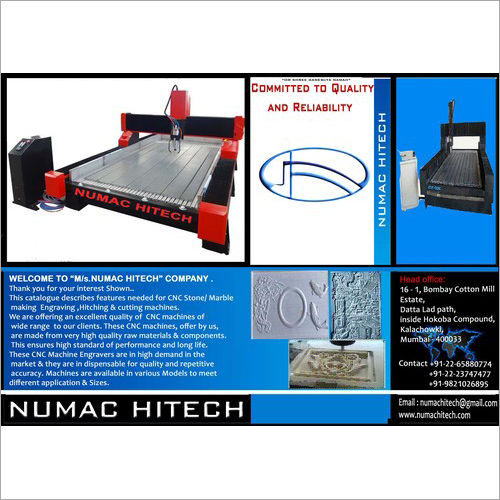

1530 Stone CNC Engraving Machine

Price 630000 INR/ Piece

1530 Stone CNC Engraving Machine Specification

- Product Type

- CNC Engraving Machine

- General Use

- Stone Engraving, Cutting, Carving

- Material

- Granite, Marble, Stone

- Type

- Stone CNC Router

- Capacity

- 3000 mm x 1500 mm

- Weight (kg)

- 1800 kg

- Computerized

- Yes

- Automatic

- Yes

- PLC Control

- Yes

- Bar Feeder

- No

- Power Source

- Electric

- Power Consumption

- 3 kW

- Rigidity

- High

- Voltage

- 380 V

- Motor

- Step Motor

- Table Size

- 1500 mm x 3000 mm

- Spindle Speed

- 0-24000 RPM

- Axial Choice

- XYZ axis

- Dimension (L*W*H)

- 2300 mm x 3400 mm x 1700 mm

- Feature

- High precision, water cooling

- Color

- Gray & Blue

1530 Stone CNC Engraving Machine Trade Information

- Minimum Order Quantity

- 1 Piece

- FOB Port

- MUMBAI

- Supply Ability

- 25 Pieces Per Month

- Delivery Time

- 1 Days

- Sample Available

- No

- Packaging Details

- WOODEN

- Main Domestic Market

- [, ]

About 1530 Stone CNC Engraving Machine

The CO2 laser machine manufactured byNumac Hitechtypically comes with various specifications depending on the model and application it is designed for. However, here's a general overview of the typical specifications that such a machine might have. For accurate specifications of a specific model, you should refer to the product's manual or Numac Hitech's official documentation.

Typical Specifications for a CO2 Laser Machine (Numac Hitech)1.Laser Type:

-

- CO2 laser (gas laser) typically using a mixture of carbon dioxide (CO2), nitrogen (N2), and helium (He) as the laser medium.

2.Laser Power:

-

- Common ranges: 40W, 60W, 80W, 100W, 150W, and 200W.

- The power rating determines the cutting and engraving capacity.

3.Laser Wavelength:

-

- The standard wavelength for a CO2 laser is 10.6 micrometers (m), suitable for various materials like wood, acrylic, glass, fabric, rubber, and more.

4.Cutting Area:

-

- Cutting bed sizes can vary based on the model, but typically sizes include:

- 300mm x 200mm

- 600mm x 400mm

- 1300mm x 900mm

- Larger formats, depending on specific machine configurations.

- Cutting bed sizes can vary based on the model, but typically sizes include:

5.Maximum Cutting Thickness:

-

- Material-dependent, but typically:

- Acrylic: 10-25 mm

- Wood: 15-25 mm

- MDF: 10-25 mm

- Leather: 5-10 mm

- Depending on power and speed settings.

- Material-dependent, but typically:

6.Cutting Speed:

-

- Adjustable, with typical ranges from0-500 mm/s, again dependent on material, power, and thickness.

7.Engraving Speed:

-

- Similar to cutting speed, adjustable with a typical range from0-1000 mm/s.

8.Control System:

-

- DSP Controller(Digital Signal Processor) is common in Numac Hitech machines for precise control of the laser head.

- Compatibility with software likeCorelDRAW,AutoCAD, andLight Burn.

- Can interface via USB, Ethernet, or directly from a PC.

9.Cooling System:

-

- Water cooling system for heat dissipation, often using aCW-3000or similar water chiller.

10.Focusing Lens:

- Typically around1.5" to 2" focal lengthlenses, which can be swapped depending on the cutting or engraving needs.

- Max Travel Speed:

- Usually up to30,000 mm/min, but variable depending on the setup.

- Electrical Requirements:

- Voltage:220Vsingle-phase or380Vthree-phase power supply depending on the machine's power rating

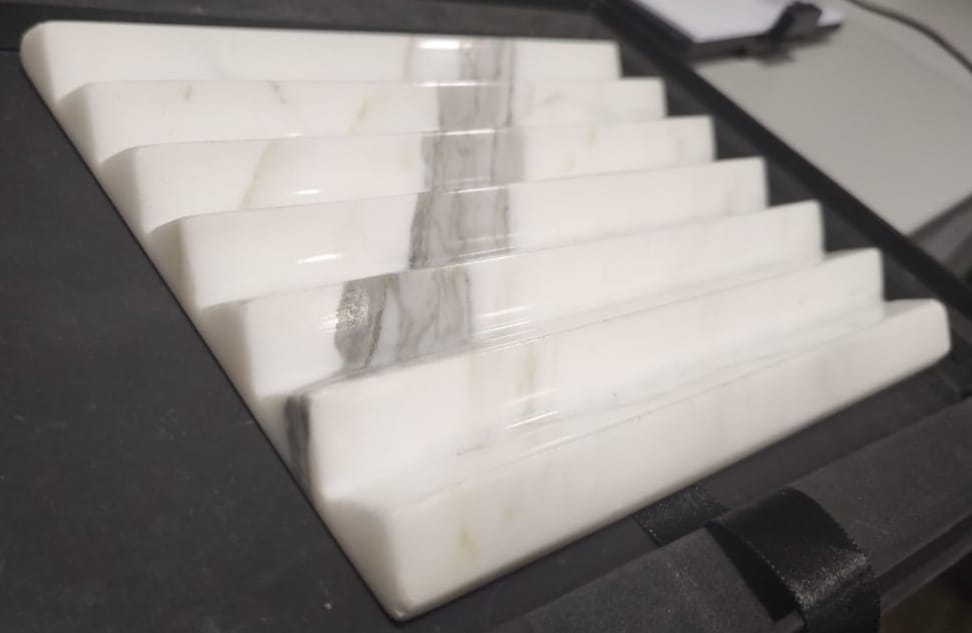

Advanced Stone Machining Precision

Delivering exceptional 0.01 mm repeat positioning accuracy, the 1530 Stone CNC Engraving Machine stands out for its reliability in detailed stone engraving and carving tasks. Its combination of a high-power water-cooled spindle, sturdy steel construction, and integrated water tank ensures both operational stability and high-quality results, even in challenging environments.

User-Friendly and Versatile Software Support

Seamlessly compatible with industry standards such as ArtCAM, Type3, and common G-code formats, the machine ensures straightforward file preparation and processing. The DSP hand-held controller and PLC system provide intuitive operation, catering both to experienced professionals and newcomers seeking efficient workflow integration.

Durability and Operator Safety

Designed with enhanced dust-proof and water-proof features, the 1530 model prioritizes both durability and operator safety during extended stone processing. Its robust structure, reliable water cooling, and optional lubrication systems contribute to increased equipment lifespan and reduced maintenance needs.

FAQ's of 1530 Stone CNC Engraving Machine:

Q: How does the 1530 Stone CNC Engraving Machine ensure high precision during stone engraving?

A: The machine achieves high precision thanks to a combination of 0.01 mm repeat positioning accuracy, a ball screw on the Z-axis, and a rigid steel frame. These features work together to minimize vibration and maintain consistent depth and detail, even with dense materials like granite and marble.Q: What types of files and software are compatible with this CNC engraving machine?

A: The machine is compatible with ArtCAM, Type3, and other commonly used G-code formats. Supported file types include DXF, PLT, NC, BMP, and JPG, enabling flexible import and workflow integration for design and production.Q: When is water cooling important, and how is it applied in this machine?

A: Water cooling is crucial during intense engraving or cutting operations to dissipate heat from the powerful 5.5 kW spindle, protecting both the tool and workpiece from overheating. The integrated water cooling system ensures stable temperatures and consistent performance, particularly during extended use.Q: Where can the 1530 Stone CNC Engraving Machine be installed and operated?

A: This model is suitable for industrial workshops, stone fabrication facilities, and manufacturing plants across India. It operates efficiently in environments with temperatures between 0-45C and requires a 380 V power source.Q: What is the process for lubricating the machine, and why is it important?

A: Lubrication can be managed manually or automatically, depending on your preference or setup. Regular lubrication is essential to reduce friction, ensure smooth axis movement, and extend the lifespan of critical components.Q: How does the transmission system contribute to the machine's performance?

A: The use of rack & pinion drives on X/Y axes allows for fast, robust movement, while the ball screw on the Z axis delivers accuracy and stability for depth control. This combination supports efficient, precise stone machining across a large work area.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in CNC Stone Engraving Machine Category

Stone CNC Router

Price 680000 INR / Unit

Minimum Order Quantity : 1 Unit

Type : CNC Router

Feature : Low Energy Consumption, High Precision, Vacuum Cleaning System, High Speed

Power Source : Electric

Material : Aluminum

CNC Stone Engraving Machine

Minimum Order Quantity : 1 Unit

Feature : High Speed

Power Source : Electric

Material : Metal

Double Head Stone Engraving CNC Router

Price 625000.0 INR / Piece

Minimum Order Quantity : 1 Piece

Type : [, ]

1325 CNC Stone Router

Price 600000.0 INR

Minimum Order Quantity : 1 Number

Type : [, ]

Feature : [, ]

GST : 27AAKHA4175N1ZV

|

|

NUMAC HITECH

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

Send Inquiry

Send Inquiry